95 Yttria Stabilized Ceramic Ball Mill Media

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | 0.1mm-50mm |

Payment & Shipping Terms:

| Minimum Order Quantity: | 25kgs |

|---|---|

| Price: | Negotiation |

| Packaging Details: | 25kgs barrels+Pallet |

| Delivery Time: | 5-20 days |

| Supply Ability: | 500mt per year |

|

Detail Information |

|||

| Commodity Name: | Yttria Stabilized Zirconia Beads | Color: | Shiny White |

|---|---|---|---|

| True Density: | 6.0g/cm3 | Bulk Density: | 3.7g/cm3 |

| Mohs Harness: | 8~9 | Impact Strength: | 2.0KN |

| Abrasion Loss: | 0.5ppm/h | Chemical Index: | ZrO2 95%Min. |

| Package: | 25kgs Barrels+Pallet | Application: | Grinding Media For Battery, Magnetic Materials, Calcium Carbonate, Titanium Dioxide, Paint, Pigment, Dye, Ink. Etc |

| Highlight: | grinding media balls,ceramic grinding balls |

||

Product Description

95 Yttria stabilized zirconia ceramic grinding media 0.1-50mm Bulk density 6.0 g/cm3

![]()

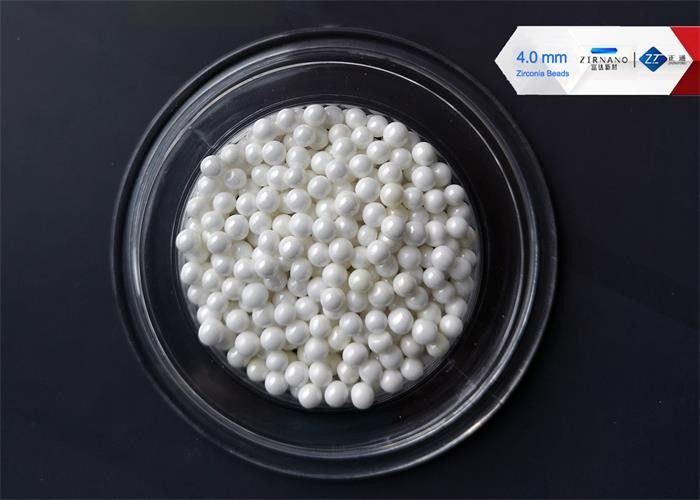

Zirconia ceramic beads is 95 Yittria-stabilized zirconia grinding beads. It is made of micro zirconia powder by sintering method. It is Shiny White color, spherical shape, with high density. High hardness and low abrasion, is high quality and high efficiency grinding media for battery materials, magnetic materials, calcium carbonate, titanium white powder, paint, pigment, dye, ink, mining and other chemical industries grinding and dispersion.

![]()

![]()

Manufacturing process: Sintering Method

| CHEMCIAL INDEX | ||||

| ZrO2 | Y2O3 | Other | Notes: Chemical composition differs depending on sizes | |

| 95% Min. | 4.5% Min. | 0.5%Max | ||

| PHYSICAL INDEX | ||||

| Specific Density | Bulk Density | Vickers Harness | Impact Strength | Abrasion Loss |

| 6.0g/cm3 | 3.7g/cm3 | 1100HV | 2.0KN | 0.5 ppm/h |

| SIZES Φ MM | ||||

| 0.1-0.2 | 0.2-0.3 | 0.3-0.4 | 0.4-0.6 | 0.6-0.8 |

| 0.8-1.0 | 1.0-1.2 | 1.2-1.4 | 1.4-1.6 | 1.6-1.8 |

| 1.8-2.0 | 2.0-2.2 | 2.2-2.4 | 2.4-2.6 | 2.6-2.8 |

| 2.8-3.0 | 4,5,6,7,8,9,10,12,15,17,20,25,30,40,50 | |||

![]()

![]()

![]()

![]()

![]()

Features

- 1. Good sphericity,smooth surface and good fluidity.

- 2. High Density, High grinding efferency

- 3. High Toughness, longlife, not break

- 4. Low Abrasion loss and zero pollution

- 5. Acid and alkali resistant

![]()

Mainly used in ultra-fine grinding and dispersion of materials of zero pollution requirement and high viscosity and high hardness.

Such as: electronic ceramics, battery materials, magnetic materials, zirconia, silica, heavy calcium carbonate, kaolin, titanium dioxide, mica, pharmaceutical foods, pigments, dyes, inks, paints, coatings and other specialty chemical industries.

![]()

- Bar pin horizonal grinding mill

- Turbine horizonal grinding mill

- Ring-type grinding mill

- Centrifugal grinding mill

- Nano Grinder

![]()

![]()

![]()

![]()

![]()

![]()

Caroline Cui

![]()