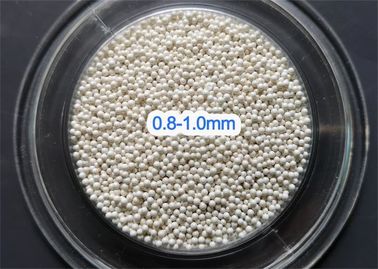

65 Zirconium Ceramic Grinding Balls 0.6 - 0.8mm Size White / Milky White Color

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | 0.6-0.8mm~10mm |

Payment & Shipping Terms:

| Minimum Order Quantity: | 25kgs |

|---|---|

| Price: | Negotiation |

| Packaging Details: | 25kgs barrels+pallet |

| Delivery Time: | 5-20 days |

| Supply Ability: | 1500mt per year |

|

Detail Information |

|||

| Commodity: | 65 Zirconium Silicate Grinding Beads | Color: | White Or Milky White |

|---|---|---|---|

| Chemical Index: | ZrO2 65%min. SiO2 30-25% | Bulk Density: | 2.5g/cm3 |

| True Density: | 4.0g/cm3 | Hardness: | 900 HV |

| Impact Strength: | 1.1KN | Package: | 25kgs Barrels+pallet |

| Highlight: | ceramic grinding balls,ceramic ball mill media |

||

Product Description

65 zirconium silicate beads grinding media for pesticide suspension

![]()

Zirconium Silicate beads is one of ceramic Grinding media, sintered and phased from imported zirconium silicate powder, with ZrO2 65% and usually called "65 Zirconium Beads". Suitable for the grinding of materials with medium and low viscosity and it can be used in most of the grinding equipment, especially the Vertical Sand Mills.

The small size 0.6-3.0mm beads are usually used for ink, paint, coating, pigment, titanium dioxide powder and pesticides grinding and dispersion

![]()

![]()

| Chemical composition | ZrO2>65% |

| SiO2 <35% | |

| True Density | 4.0g/cm3 |

| Bulk density | 2.5g/cm³ |

| Wear rate per ton | 0.03kg/h |

| Moh's hardness | 8 |

| Color | Milky white |

| Package | 25kg/ barrel |

Size (Diameter/mm) :

| 0.1-0.2 | 0.2-0.3 | 0.3-0.4 | 0.5-0.6 |

| 0.6-0.8 | 0.8-1.0 | 1.0-1.2 | 1.0-1.2 |

| 1.4-1.6 | 1.6-1.8 | 1.8-2.0 | 2.0-2.2 |

| 2.2-2.4 | 2.4-2.8 | 2.8-3.2 | 4,5,6,7,8,9,10 |

![]()

![]()

![]()

- Good sphericity-Low abrasion loss, long life time. Wearability is 8-10 times higher than glass beads;

- High Density-High Grinding efficiency. Grinding efficiency is 3-5 times higher than glass beads;

- High crushing strength, reduce the intermal friction between the beads and improve the material flow efficiency

- Good icid and alkali-resistance and good chemical stability

![]()

Grinding & dispersion for :

- Ink,

- Paint,

- Coating,

- Pigment,

- Titanium dioxide powder

- Pesticides

| 1 | Open vertical sand mills | 2.0-3.0mm zirconium silicate beads or zirconia beads |

| 2 | Closed vertical sand mills | 0.6-3mm zirconium silicate beads or zirconia beads |

| 3 | Traditional horizontal sand mills | 1.0-3.0mm glass beads or zirconium silicate beads. |

| 4 |

Horizontal pin sand mills |

0.6-2.0mm zirconia beads |

| 5 | Turbine horizontal sand mills | 0.4-2.0mm zirconium silicate beads or zirconia beads. |

| 6 | Special-shaped cylinder sand mill | 1.0-2.0mm zirconium silicate beads |

| 7 |

Profiled disc sand mills |

0.6-2.5mm zirconium silicate beads or zirconia beads |

| 8 | Ring type sand mills | 0.4-1.5mm zirconia beads |

| 9 | Centrifugal sand mills | 0.05-0.80mm zirconia beads. |

| 10 | Basket Type sand mills |

1.0-3.0mm zirconium silicate beads or zirconia beads |

![]()

-

Open vertical sand mills,

-

Closed vertical sand mills

-

Traditional horizontal sand mills

-

Turbine horizontal sand mills

-

Special-shaped cylinder sand mills.

-

Profiled disc sand mills

![]()

![]()

![]()

Caroline Cui

![]()