White Plastic Bead Blasting Media Wear Resistant Nylon Sand PA 1.13 G/Cm3 Bulk Density

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | PA10-PA120 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 25 KG |

|---|---|

| Price: | Negotiable |

| Packaging Details: | 25 Paper bag+Pallet |

| Delivery Time: | Within 3-5 days after order confirmed |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 3000 MTS Per Year |

|

Detail Information |

|||

| Commodity: | Nylon Sand | Product Name: | PA Plastic Blasting Media |

|---|---|---|---|

| Application: | Deburring | Hardness: | 120 HRC |

| Bulk Density: | 1.13 G/cm3 | Tensile Force: | 750 Kg/cm2 |

| Specification: | PA10-PA120 | Free Sample: | Available |

| Highlight: | plastic bead blasting media,plastic sandblasting media |

||

Product Description

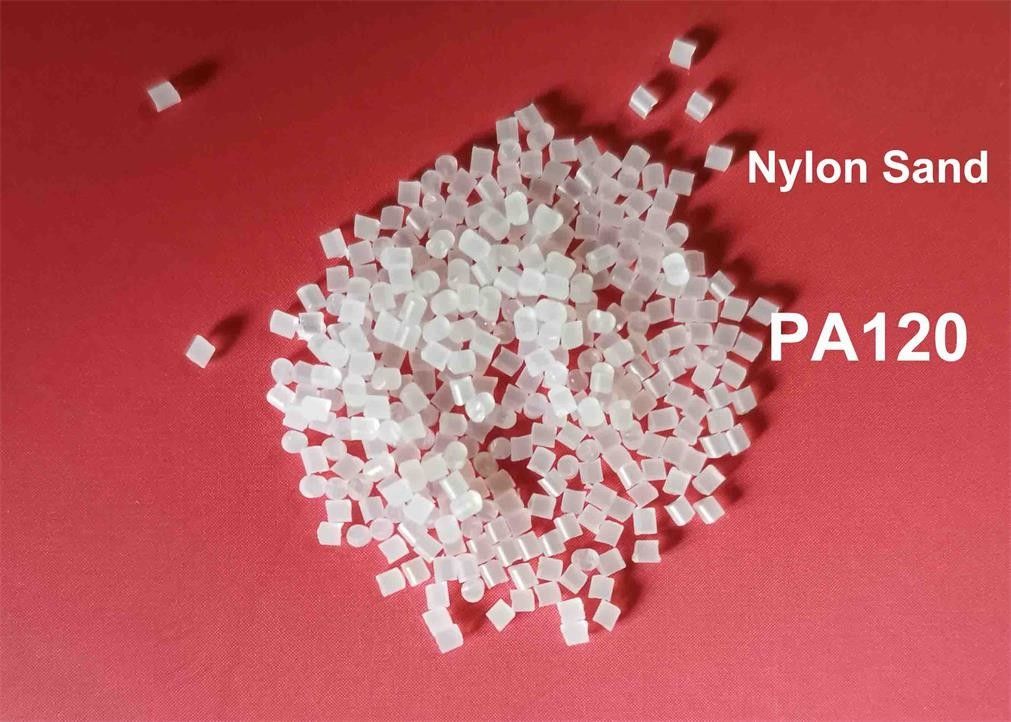

White Wear-resistant Nylon Sand PA Plastic Blasting Media for Deburring

1. Product Description of Nylon Sand

The main material of nylon sand is Polyamide(PA),it is one translucent milky white crystalline thermoplastic

polymer particles,produced by a special formula PA6 monofilament through one high-speed pelletizer.

2. Main Specification of Nylon Sand

| Size | Diameter*Length mm | Color |

| PA10 | 0.10*0.10 | White |

| PA15 | 0.15*0.15 | White |

| PA20 | 0.20*0.20 | White |

| PA30 | 0.30*0.30 | White |

| PA40 | 0.40*0.40 | White |

| PA50 | 0.50*0.50 | White |

| PA60 | 0.60*0.60 | White |

| PA80 | 0.80*0.80 | White |

| PA100 | 0.80*0.80 | White |

| PA120 | 1.00*1.00 | White |

|

Remark: Dimension accuracy ±0.05mm Special specification and color can be customized |

||

3. Why Nylon sand is one ideal surface treatment blasting media?

Nylon sand is soft and weak, with certain toughness, no cutting property, no damage to treated workpieces,

it will reduce the defect rate of the treated workpieces,not only remove the burrs and throns on the surface

of treated workpiece,but also no damage to treated workpieces.

4. Main Applications of Nylon Sand

Remove the spilled glue In the electronics industry:surface pre-treatment for the circuit board , spilled

glue removal for electronic parts.

Clean epoxy optical detector: do not make the surface opaque;

Composite material: Remove the coating layer from glass fiber, carbon fiber and resin workpieces;

Mold cleaning: clean various molds such as rubber molds, plastic molds, glass molds and die-casting

mold without damaging the dimensional accuracy of the mold;

Aircraft paint removal: remove most paint of the aircraft, but retain the plating;

Deburring: Remove small and slight burrs without damaging the surface of the workpiece.

![]()