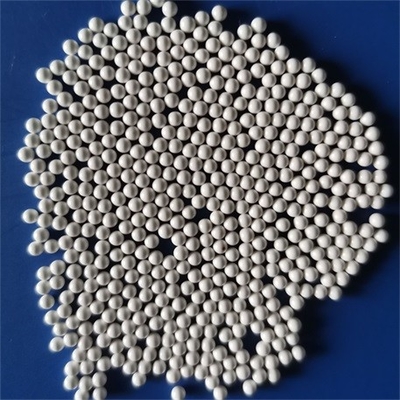

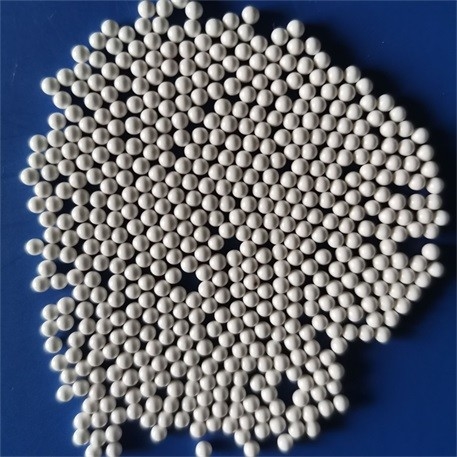

65 Zirconium Silicate Beads Grinding Media For Metallic And Non-Metallic Minerals

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | 0.2-10mm |

Payment & Shipping Terms:

| Minimum Order Quantity: | Negotiable |

|---|---|

| Price: | Negotiable |

| Packaging Details: | 25kg barrel+ Pallet |

| Delivery Time: | Within 3-5 days after order confirmed |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 500mt per Year |

|

Detail Information |

|||

| Commodity: | Zirconium Silicate Beads | Product Name: | 65 Zirconia Beads |

|---|---|---|---|

| Usage: | Grinding Media | Main Chemical: | 65% ZrO2, 25-30% Al2O3 |

| Bulk Density: | ≥2.5 G/cm3 | True Gravity: | ≥4.0 G/cm3 |

| Vicker Hardness: | ≥700HV | Product Process: | Sintering |

| Highlight: | 65 Zirconium Silicate Beads,Zirconium Silicate Beads For Metallic,Zirconium Silicate Beads For Non Metallic |

||

Product Description

65 Zirconium Silicate Beads Grinding Media For Metallic and Non-metallic Minerals

1. Product Description of 65 Zirconium Silicate Beads

Zirconium silicate beads is also called as 65 zirconia beads, it selects the high-purity ultra-fine zirconium

silicate powder as main materials,then sintered by special technology.

65 zirconia beads has uniform microcrystalline structure and has higher strength than fused ceramic sand.

2. Main Technical Data of 65 Zirconium Silicate Beads

| Commodity | Process | Chemical Index | Physical Index |

| Zirconium Silicate Beads | Sintering | ZrO2 ≥ 65% | Bulk density:2.5g/cm3 |

| SiO2 25-30% | True Gravity ≥4.0 g/cm3 | ||

| Others ≤1.0% | Vicker Hardness≥700 HV | ||

| Particle Size(diameter) | 0.2-0.4mm 0.4-0.6mm 0.6-0.8mm,0.8-1.0mm, | ||

| 1.0-1.2mm,1.2-1.4mm,1.4-1.6mm,1.6-1.8mm,1.8-2.0mm | |||

| 2.0-2.2mm,2.0-2.5mm,2.5-3.0mm ,3.0-3.5mm | |||

| 4mm,5mm,6mm,7mm,8mm,10mm etc. | |||

| Remark: Special specification can be customized | |||

3. Main Features of Zirconiun Silicate Beads

Higher true gravity,higher grinding efficiency compared with glass beads at same grinding condition;

High strength due to its uniform and dense crystal structure;

No contamination to the treated materials;

Good sphericity and smooth surface,little damage to the grinding equipments.

4. Main Applications of Zirconiun Silicate Beads

Mainly used for ultra-fine grinding of metallic and non-metallic minerals such as gold, silver, nickel, zinc

and lead ore, heavy calcium, zirconium silicate, titanium dioxide and paints, coatings, pigments and inks.

![]()

5. Why Choose us?

Professional manufacturer and technical staffs;

Stable quality and strict quality control system,all the products can be traced in each step.

Quick response,competitive price,fast delivery;

7*24hrs professional service before and after sales.