ZrO2 65% Zirconium Silicate Ball 900HV Harness 1.1KN Impact Strength White Color

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | 0.6-0.8mm~10mm |

Payment & Shipping Terms:

| Minimum Order Quantity: | 25kgs |

|---|---|

| Price: | Negotiation |

| Packaging Details: | 25kgs barrels+Pallet |

| Delivery Time: | 2-20 days |

| Supply Ability: | 3000mt per year |

|

Detail Information |

|||

| Commodity Name: | Zirconium Silicate Beads Grinding Media | Color: | White |

|---|---|---|---|

| Bulk Density: | 2.5g/cm3 | True Density: | 4.0g/cm3 |

| Harness: | 900HV | Impact Strength: | 1.1KN |

| Package: | 25kgs Barrels+Pallet | Port Of Loading: | Tianjin/Qingdao, China |

| Highlight: | ceramic grinding media balls,zirconium silicate media |

||

Product Description

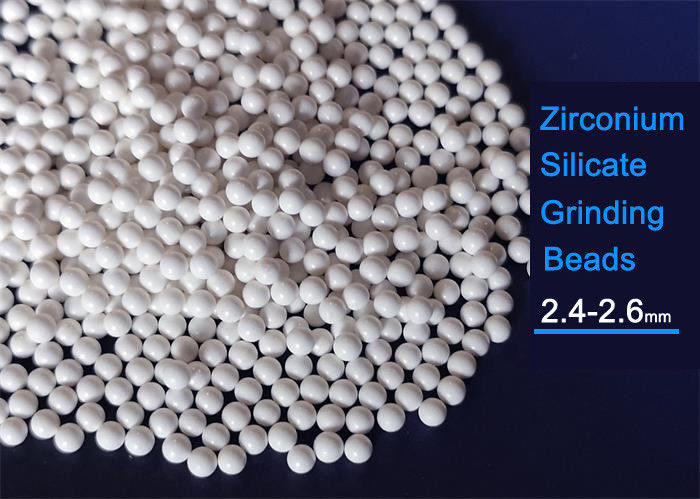

ZrO2 65% Zirconium Silicates grinding beads for coating milling and grinding 2.4-2.6mm

| l Product Name | |||||

| Fast delivery ZrO2 65% Zirconium Silicates grinding beads for coating milling and grinding | |||||

| l Commodity Description | |||||

| 65 zirconium silicate beads are produced by sintering method. The internal crystal structure is uniform and fine. It is a widely used and cost-effective grinding media. It is mainly used for grinding of calcium carbonate, kaolin, titanium dioxide, coatings, paints, inks and other industries. It is applicable for nano sand mill, horizontal sand mill, vertical sand mill, laboratory sand mill, basket sand mill, etc. | |||||

| l Chemical & Physical Index | |||||

| Chemical Index | Production Process | True Density | Bulk Density | Hardness | |

| Vickers | Mohs | ||||

|

ZrO2 :65% SiO2: 35% |

Sintering | 4.0 | 2.5 | 900HV | 7.5 |

| l Sizes | |||||

| Φ 0.6-0.8mm | Φ 0.8-1.0mm | Φ1.0-1.2mm | |||

| Φ 1.2-1.4mm | Φ 1.4-1.6mm | Φ1.8-2.0mm | |||

| Φ 2.0-2.2mm | Φ2.0-2.5mm | Φ2.5-3.0mm | |||

| Φ 4 mm | Φ 5 mm | Φ 6 mm | |||

| Φ 7 mm | Φ 8 mm | Φ 9 mm | |||

| Φ 10 mm | / | / | |||

| l Features of Zirconia grinding beads | |||||

|

a. The internal structure of zirconium silicate beads is uniform and dense, which always makes the quality of the grinding material uniform. b. It has better toughness, impact resistance, and very small friction coefficient, which makes the wear of the beads on the equipment very low. c. High density, significantly improve grinding effect and efficiency d. Low wear and long service life. |

|||||

| l Parameters- (Comparing with 95 Zirconia Grinding beads) | |||||

| Parameters | 95 Y-TZP Zirconia Grinding Beads | 65 Zirconium Silicate Beads | |||

| Chemical index | ZrO2+Y2O3 | ZrO2+SiO2 | |||

| Chemical stability | Good | Better | |||

| Vickers Hardness | 1100HV | 900HV | |||

| True Density | 6.0g/cm3 | 4.0 g/cm3 | |||

| Bulk Density | 3.7g/cm3 | 2.5g/cm3 | |||

| Size range | 0.1-50mm | 0.6-10mm | |||

| Shape | spherical | spherical | |||

| Metal Pollution | no | no | |||

| Wear loss | 0.6% | 0.75% | |||

| Application |

Grinding and milling media in below industries: 1. Wear and corrosion resistant products like coating, pigment, ink and dyeing |

Grinding mainly for calcium carbonate, kaolin, titanium dioxide, paint, paint, etc. | |||

| l Applicable Equipment | |||||

|

1. Nano sand mill 2. Horizontal sand mill 3. Vertical sand mill 4. Laboratory sand mill 5. Basket sand mill |

|||||

| l Package | |||||

| 25kgs /Barrel+Pallet | |||||

![]()