150# 30 Mesh NFS Black Spherical Ceramsite Sand

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | 14Mesh-270Mesh |

Payment & Shipping Terms:

| Minimum Order Quantity: | 25 MT |

|---|---|

| Price: | Contact us |

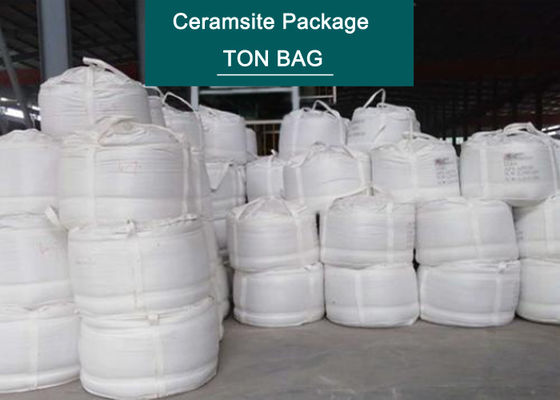

| Packaging Details: | 25kgs bags +Ton bags |

| Delivery Time: | 5-8 working days |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100000mt per year |

|

Detail Information |

|||

| Materiall: | Ceramsite | Main Chemical Index: | Al2O3 75% Min. SiO2 18% Max. |

|---|---|---|---|

| Refractoriness: | 1800 ℃ Min. | Bulk Density: | 1.65-1.95g/cm3 |

| True Density: | 3.3g/cm3 | PH Value: | 7-8 |

| Thermal Expansion Rate: | 0.13% (1000℃, Heating 10 Minutes) | Angle Coefficient: | ≤ 1.1 (Extramely Like Spheric) |

| Highlight: | Black Spherical Ceramsite Sand,30 Mesh Ceramsite Sand,150# Ceramic Foundry Sand |

||

Product Description

Black spherical Fused Ceramsite Sand Foundry Material 150# 20-30 Mesh

- Description

Ceramsite, also called as Fused ceramic sand, or NFS CERAMSITE-Nice Foundry Sand, is a kind of spherical shape ceramic particles featured by high refractoriness, low thermal expansion melted from the fused bauxite.

It provides a simple and efficient way in the foundry industry to improve the quality of the castings, reducing the production cost and avoiding environmental pollution, so it is much better than silica sand. And it is also good substitution to Chromite sand and Zircon sand because of its lower price. At the present, Ceramsite is acknowledged in the worldwide as the ideal sand for the foundries and has a wide feasibility of applications for the future development.

- Specification

Chemical Index

| Index | Al2O3 | SiO2 | Fe2O3 | TiO2 | K2O+Na2O | CaO+MgO | L.O.I |

| Content | 75% Min. | 18% Max. | 3% Max. | 3.5% Max. | 1% Max. | 1% Max. | 0.3% Max. |

Technical Index

| Index | Refractories | Bulk Density | True density | Angle coefficient |

| Content | 1800 ℃ | 1.65-1.95g/cm3 | 3.3g/cm3 | 1.1 Max. |

| Index | PH Value | Moisture | Mud Content | Thermal expansion rate |

| Content | 7-8 | 0.1% Max. | 0.1% Max. | 0.13% |

|

μm Mesh |

1700 | 850 | 600 | 425 | 300 | 212 | 150 | 106 | 75 | 53 | Pan | AFS | # |

| 10 | 20 | 30 | 40 | 50 | 70 | 100 | 140 | 200 | 270 | ||||

| 20/40 | ≤ 2 | 15-40 | 30-55 | 15-35 | ≤ 3 | 15-25 | 200# | ||||||

| 30/50 | ≤ 10 | 25-45 | 35-55 | 5-15 | ≤ 5 | ≤ 2 | 25-29 | 300# | |||||

| 40/70 | ≤ 10 | 25-45 | 20-40 | 15-25 | ≤ 7 | ≤ 5 | 35-39 | 400# | |||||

| 40/100 | ≤ 3 | 10-25 | 25-40 | 25-45 | 10-20 | ≤ 10 | ≤ 5 | 45-55 | 500# | ||||

| 50/100 | ≤ 10 | 10-30 | 30-50 | 15-35 | ≤ 15 | ≤ 5 | ≤ 2 | ≤ 1 | 55-65 | 600# | |||

| 50/140 | ≤ 8 | 10-25 | 20-40 | 20-40 | 5-20 | ≤7 | ≤ 2 | ≤ 1 | 60-70 | 650# | |||

| 70/140 | ≤ 10 | 10-25 | 25-45 | 15-35 | ≤15 | ≤ 5 | ≤ 2 | 75-85 | 750# | ||||

| 100/200 | ≤ 3 | 10-30 | 35-55 | 15-35 | ≤10 | ≤ 5 | 95-115 | 1000# | |||||

| 140/270 | ≤ 5 | 5-25 | 40-60 | 25-40 | ≤15 | 155-175 | 1500# |

Features:

1. Low thermal expansion, can reduce the casting flaw, and improve dimensional accuracy.

2. Neutral material, can work with acids and alkalis.

3. Cost-effective compared with the chromite sand and zircon sand, its price is only 30-50% of zircon sand and chromite sand.

4. Spherical shape and small surface, the resin can be reduced 30-50%

5. Good refractoriness with mulite in it, easy to collapsing.

Application:

Ceramsite sand is widely used in loast foam castings.

The advantage of ceramsite in lost foam casting is that it can be recycled and reused as its high refractoriness of 1800 degrees and of good stability,.

In the lost foam casting process, the filling sand actually does not use the adhesive, only need to vacuum in the sand box to ensure the strength of the ceramsite sand. Therefore, the cost of filling sand is quite low, and can be used repeatedly, greatly reduces the cost of using foundry sand.

![]()

Full applications of Ceramsite sand as below:

Lost Foam casting

Hot core box casting

Cold box process casting

Self-setting sand

Investment casting

Large steel casting

Precision casting

Drainage sand

Refractory Coating

3D printing

Contact us and know more ...