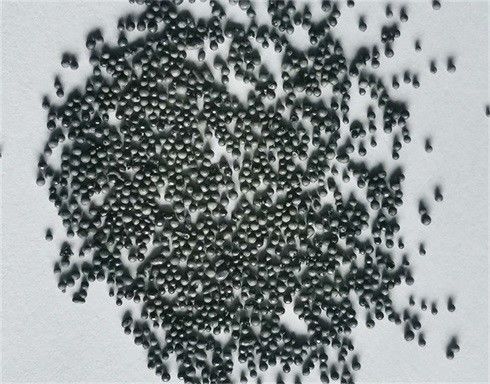

Casting Drainage 20/40# Fused Ceramic Foundry Sand

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | 14#-270# |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1000kgs |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Ton Bag |

| Delivery Time: | 3-7 days after order confirmed |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 2500mt per month |

|

Detail Information |

|||

| Commodity: | Ceramic Foundry Sand | Product Name: | Fused Ceramic Sand |

|---|---|---|---|

| Color: | Grey Brown | PH Value: | 7-8 |

| Refractoriness: | ≥1790 ℃ | Bulk Density: | 1.9-2.1g/cm3 |

| True Gravity: | 3.3g/cm3 | Average Coefficient Of Linear Expansion: | ≤6*10-6℃-1 |

| Highlight: | 20/40# Fused Ceramic Foundry Sand,Fused Ceramic Foundry Sand,Drainage Fused Ceramic Sand |

||

Product Description

High Refractoriness Ceramsite Ceramic Sand 20/30#,20/40# For Drainage Sand

1. Product Description of Ceramic Sand

Ceramsite sand is also called as ceramic foundry sand,it selected the high quality bauxite as main material,

then fused in arc furnace,finally made into different size through special technology.

It contains 70% Min Al2O3,its chemical composition is very similar to the one of black fused alumina,while

they are quite different since they are made through different technology after the melting process, then

achieved different shape and applications. Ceramsite sand is mainly used for casting industries,while black

fused alumina is used for abrasives,anti-skip roads etc.

2. Main Technical Data of Ceramic Sand

| Commodity | Main Chemical Index | Main Physical Index |

| Ceramic Sand | Al2O3 ≥70% Fe2O3 ≤3% SiO2≤18% TiO2≤3.5% K2O3+Na2O <1% CaO+MgO<1% L.O.I <0.3% |

Shape: Round Color:Gray Brown Refractoriness:≥1790 ℃ Bulk Density:1.9-2.1g/cm3 True Gravity:3.30g/cm3 Coefficient of Expansion:0.13% (Heat 10Minutes under 2000℃) PH:7-8 Thermal Conductivity:0.698W/m*K (Heated Surface 800℃) Angle coefficient:≤1.1 (Very similar to spherical) Water Content≤0.1% Mud Content≤0.1% Average Coefficient of Linear Expansion≤6*10-6℃-1 |

| Grit Size | 14#,20#,30#,40#,50#,70#,100#,140#,200#,270# | |

| Section Sand | 14/20,20/30,20/40,20/50,30/50,40/50,40/70,50/100 | |

| 50/140,70/140,70/200,100/200,140/270,200/270 | ||

| Remark | Special specification can be customized | |

3. Main Features of Ceramic Sand

High refractoriness over 1790℃;

Good sphericity;

High recycle utilization rate;

Good collapsibility;

Low thermal expansion.

4. Main Applications of Ceramic Foundry Sand:

Widely used resin sand: phenolic resin coated sand,hot-core box resin sand,blow hardening cold core resin

sand,self-hardening sand;

Lost Foam casting;

Investment casting;

Sodium silicate sand;

Casting coating;

Drainage sand;

Alloy surface treatment.

![]()

5. Why ceramsite is widely used in lost foam casting?

Ceramsite effectively solves casting defects such as sand inclusions and pores,improve the product quality,

reduce the cleaning and grinding costs, also increase the product yield by 7-10%.

Ceramsite has good abrasion resistance, low dust,its annual loss rate does not exceed to be 5%.

So it is widely used for lost foam casting industries,suitable for production of casting iron,casting steel,hadifield

steel etc.

6. How Ceramic sand affects the quality of casting quality?

The alumina content of ceramic sand will affect its crushing rate &durability,so casting made by different materials has

different alumina requirement for ceramic sand.High alumina ceramic sand is required when needing multiple strong

regeneration;

The mud content of ceramic sand also affects the casting quality;

The average fitness and particle size distribution also affects the casting quality.