Low Thermal Expansion Rate Ceramic Foundry Sand Ceramsite For Lost Foam Casting

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | 14#-270# |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1000kgs |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Ton Bag |

| Delivery Time: | 3-7 days after order confirmed |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 2500mt per month |

|

Detail Information |

|||

| Commodity: | Ceramsite Foundry Sand | Product Name: | Fused Ceramic Sand |

|---|---|---|---|

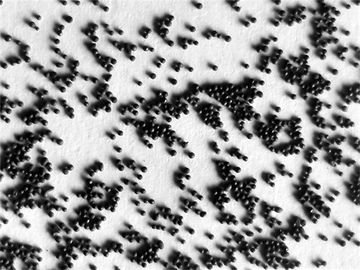

| Color: | Grey Brown | Shape: | Spherical |

| Refractoriness: | ≥1790 ℃ | Bulk Density: | 1.9-2.1g/cm3 |

| True Gravity: | 3.3g/cm3 | Average Coefficient Of Linear Expansion: | ≤6*10-6℃-1 |

| Highlight: | casting Fused Ceramic Sand,14# Ceramsite Foundry Sand |

||

Product Description

Low Thermal Expansion Rate Ceramsite Foundry Sand Fused Ceramic Sand 14#-270#

1. Product Description of Ceramsite Foundry Sand

Ceramsite Foundry Sand is also called as Fused ceramic sand,it selected the calcined bauxite

as main material, then fused, sprayed,screened into different specifications,which is mainly

used for foundry industries.

It is an advanced substitute for quartz sand.

2. Main Technical Data

| Commodity | Main Chemical Index | Main Physical Index |

|

Ceramsite Foundry Sand |

Al2O3 ≥75% Fe2O3 ≤3% SiO2≤18% TiO2≤3.5% K2O3+Na2O <1% CaO+MgO<1% L.O.I <0.3% |

Shape: Spherical Color:Gray Brown Refractoriness:≥1790 ℃ Bulk Density:1.9-2.1g/cm3 True Gravity:3.30g/cm3 Coefficient of Expansion:0.13% (Heat 10Minutes under 2000℃) PH:7-8 Thermal Conductivity:0.698W/m*K (Heated Surface 800℃) Angle coefficient:≤1.1 (Very similar to spherical) Water Content≤0.1% Mud Content≤0.1% Average Coefficient of Linear Expansion≤6*10-6℃-1 |

| Grit Size | 14#,20#,30#,40#,50#,70#,100#,140#,200#,270# | |

| Section Sand | 14/20,20/30,20/40,20/50,30/50,40/50,40/70,50/100 | |

| 50/140,70/140,70/200,100/200,140/270,200/270 | ||

| Remark | Special specification can be customized | |

3. Main Features of Ceramsite Foundry Sand

Dense structure,smooth surface,good fluidity and filling;

Low thermal expansion rate, high product size accuracy, few cracks and defects, high casting yield;

Good crushing resistance: Ceramsite hasdense structure and high strength, it is not easy to be broken

down after repeated regeneration, high recycling rate and low waste sand emission rate

Low bulk density: ceramsite has lower bulk density compared with the one of zicon sand and Chromite

ore,which will reduce the cost of high quality molding sand.

4. Main Applications:

Widely used for resin sand casting, coated sand, refractory coating and lost foam casting, V method

casting, shell casting, precision casting;

Widely used in casting molding process such as aerospace, shipbuilding, railway locomotive, wind power,

high-end pump valve, machine tool, engine, auto parts, mining machinery and other industries.

Widely used in Ladle drainage sand, soluble mold core, surface shot peening, etc.

![]()

5. Why Ceramsite is widely used in casting industry?

Ceramsite is one non-quartz type artificial sand, which can greatly improve the quality of castings, easy

to be cleaned , and the sand matching process is simple and convenient, which can reduce the coating

cost of most castings, especially suitable for making high-quality castings;

Ceramsite has the advantages of high refractoriness, good fluidity and high air permeability, which can

solve the defects in the casting production to a certain extent;

Ceramsite effectively solves the problems of high casting cost and poor casting quality.

Therefore, it is gradually replacing quartz sand or forsterite sand, then widely used in the casting industry.