65 Zirconia Beads Zirconia Ceramic Balls For Grinding / Dispersion Media

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | 0.1-10mm |

Payment & Shipping Terms:

| Minimum Order Quantity: | 5KG |

|---|---|

| Price: | Negotiable |

| Packaging Details: | 25kg barrel + Pallet |

| Delivery Time: | 3-5 days after order confirmed |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 200mt per year |

|

Detail Information |

|||

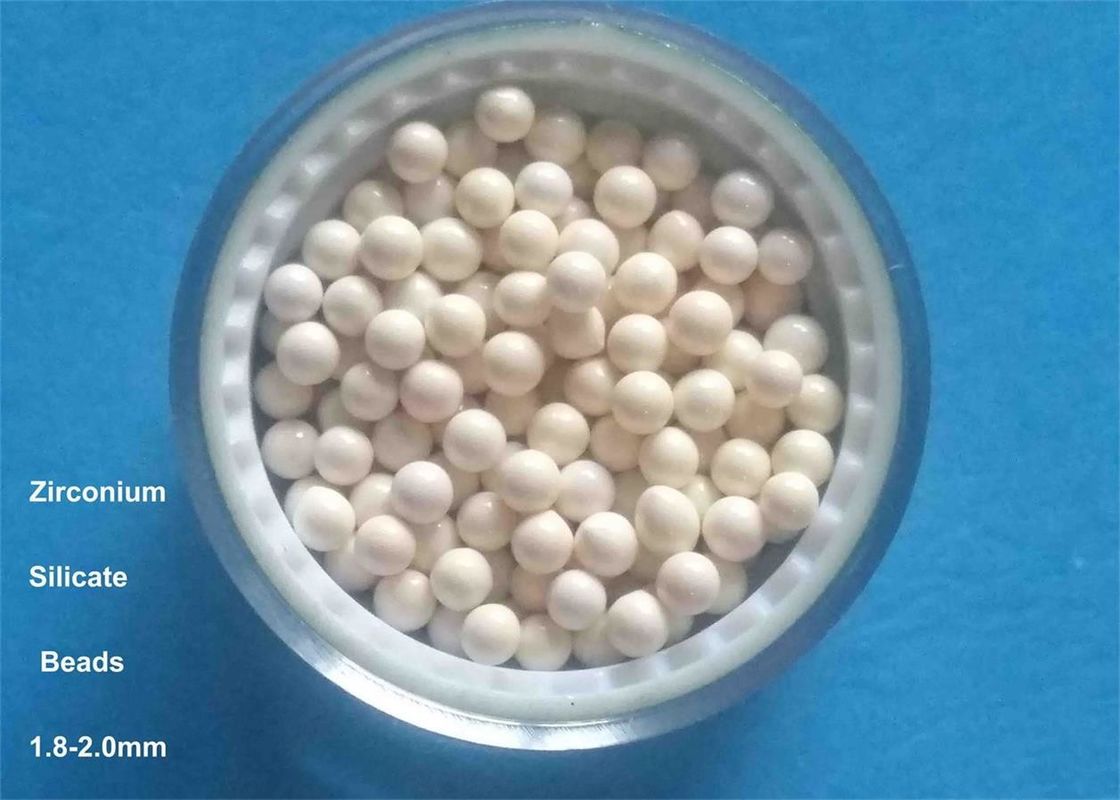

| Commodity: | Zirconium Silicate Beads | Product Name: | Zirconia Beads |

|---|---|---|---|

| Usage: | Grinding Media | Main Chemical: | 65 ZrO2 |

| True Gravity: | ≥4.0g/cm3 | Bulk Density: | ≥2.5g/cm3 |

| Vicker Hardness: | ≥900 HV | Process: | Sintering |

| Highlight: | ceramic grinding media balls,zirconium silicate media |

||

Product Description

65 Zirconia Beads Zirconium Silicate Beads for Grinding and Dispersion Media

1. Description of Zirconium Silicate Beads

Zirconium silicate bead contains about 65% ZrO2,then it is also called as 65 zirconia beads,65 zirconia.

It is made by an advanced process,there is no cores and cavities in the beads.

It has the characteristics of medium hardness and gravity,especially suitable for grinding and dispersion

of medium or low viscosity slurries. Zirconia Silicate beads is able to match most sand mills.

It is also one general grinding media in many applications.

2. Main Technical Data of Zirconium Silicate Beads

| Zirconium Silicate Beads | |

| Typical Chemical Index | Main Physical Index |

| ZrO2 ≥65% | True Gravity ≥4.0g/cm3 |

| SiO2 25-30% | Bulk Density ≥2.5g/cm3 |

| Others ≤1.0% | Vicker Hardness ≥900 HV |

| sintering process | compressive strength ≥1.1KN (Φ2mm) |

| Particle Size |

| 0.1mm,0.2-0.4mm 0.4-0.6mm 0.6-0.8mm,0.8-1.0mm,1.0-1.2mm, |

| 1.2-1.4mm,1.4-1.6mm,1.6-1.8mm,1.8-2.0mm,2.5-3.0mm ,3.0-3.5mm |

| 4mm,5mm,6mm,7mm,8mm,10mm etc. |

| Special products can be customized |

3. Package of Zirconium Silicate Beads

![]()

4. The Main Features of Zirconium Silicate Bead

- Low abrasion rate and good toughness compared with the alumina beads;

- Medium hardness and gravity,lower cost compared with 95 zirconia beads.

5. Main Applications of 65 Zirconia

Zirconium silicate bead is mainly used for the ultra-fine grinding of calcium carbonate, kaolin, titanium

dioxide, paints, paints, inks, etc.

6. Applicable Equipment:

- High speed mixing mill

- Vibration Mill

- Grinder Mill