Pigment Zirconium Silicate Beads Milling Media 1.6 - 1.8 mm Size Low Abrasion

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | 0.6-10mm |

Payment & Shipping Terms:

| Minimum Order Quantity: | 25kg |

|---|---|

| Price: | Negotiation |

| Packaging Details: | 25kg drum+Pallet, 25kg Bag+Pallet,Ton Bag |

| Delivery Time: | 3-14days depending on the order quantity |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 3000MT per Year |

|

Detail Information |

|||

| Product Name: | Zirconium Silicate Beads | Usage: | Dispersion Of Ink Slurry |

|---|---|---|---|

| Compressive Strength: | ≥1.1 KN (Φ2mm) | Vicker Hardness: | ≥900 HV |

| True Gravity: | ≥4.0g/cm3 | Bulk Density: | ≥2.5g/cm3 |

| Process Method: | Sintering | ||

| Highlight: | zirconia sintering beads,zirconium silicate media |

||

Product Description

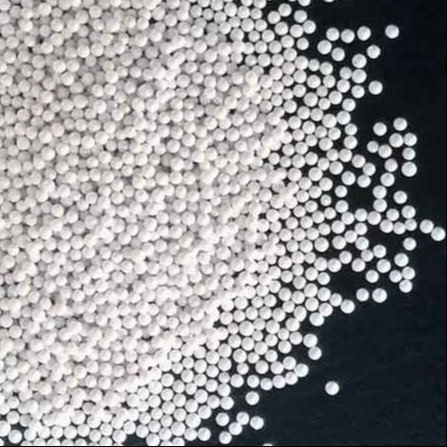

Low Abrasion Zirconium Silicate Beads Zirconia Milling Media 1.6 - 1.8 mm For Pigment

1. Description of Zirconium Silicate Beads

Zirconium Silicate beads are manufactured by Zirconium Sand with the special sinitering technology,

it has the characteristics of medium density and hardness as well as competitive price advantages.

It is widely used as one grinding and dispersing media.

2. Main technical index of Zirconium Silicate Beads

| Commodity | Typical Chemical Index | Main Physical Index |

|

Zirconium Silicate Beads Zirconia Grinding Media (Sinterred Process) |

ZrO2 ≥65% | True Gravity ≥4.0g/cm3 |

| SiO2 25-30% | Bulk Density ≥2.5g/cm3 | |

| Others ≤1.0% | Vicker Hardness ≥900 HV | |

| Sintering process | compressive strength ≥1.1KN (Φ2mm) |

| Particle Size | ||||||

| Φ0.6-0.8mm,Φ0.8-1.0mm,Φ1.0-1.2mm,Φ1.2-1.4mm,Φ1.4-1.6mm | ||||||

| Φ1.6-1.8mm,Φ1.8-2.0mm,Φ2.5-3.0mm ,Φ3.0-3.5mm | ||||||

| Φ4mm,Φ5mm,Φ6mm,Φ7mm,Φ8mm,Φ10mm etc. | ||||||

| Special products can be customized |

3. Main Features of Zirconium Silicate Beads

Low abrasion rate and high grinding effect due to its dense crystalline form;

Good Sphericity offers better fluidity and higher throughput of treated slurry;

Smooth surface and high density provides few damage to the grinding equipment and little

contamination to the slurry as well as easy to change the slurry color;

More concentrated particle size distribution, ensures narrower particle size distribution of grinding slurry.

5. Main Application of Zirconium Silicate Beads

Widely used as one high efficiency grinding,dispersing media for pigments such as Tio2,carbon black,

cromophtal yellow etc.

In addition,it is also widely used as one grinding media for coating,paint,ink, titanium dioxide,pesticide etc.

6. Products Package

25kg drum+pallet, 25kg bag +pallet, ton bag,special packages can be customized.

![]()

7. Why Choose Us?

Professional manufacturer,Providing good products with stable quality & favorable price;

Equipped with the most advanced production line and testing equipments,certificatd by

ISO9001&14001;

Products has been exported to USA,South Korea,Vietnam,Japan etc.