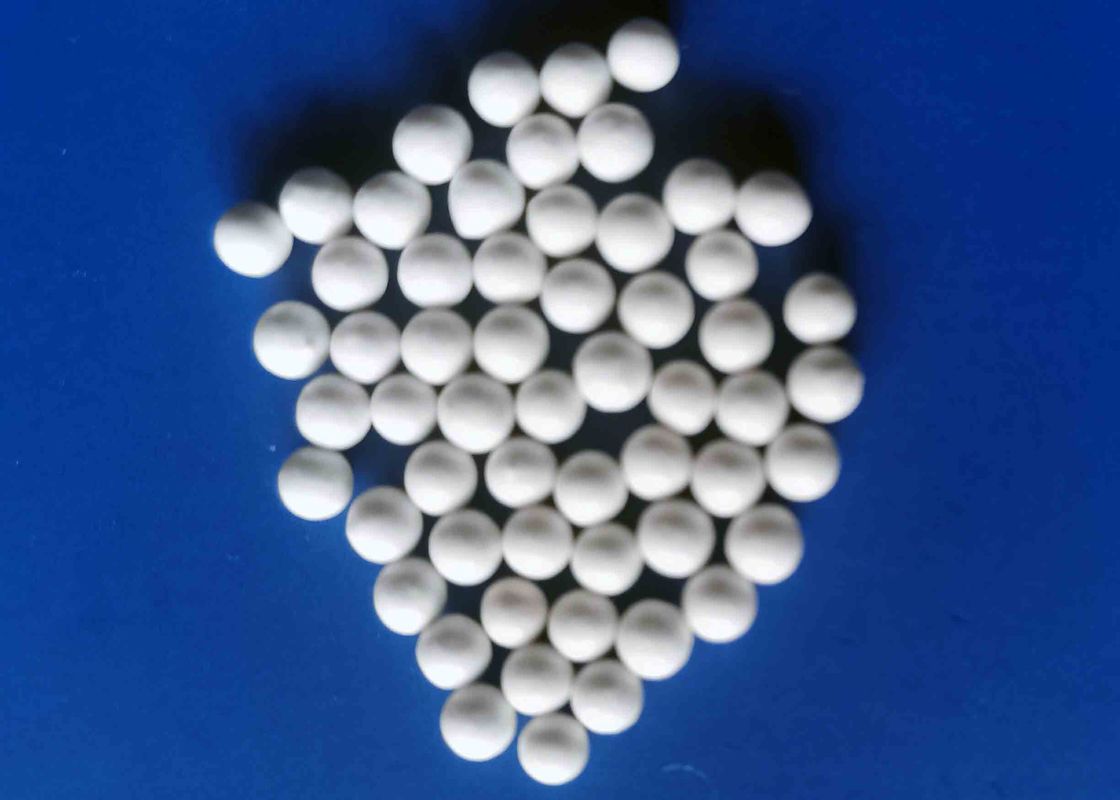

65 Zirconium Silicate Beads / Zirconia Grinding Media 2.8-3.0 Mm For Paint , Coating , Ink

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | 0.2-10mm |

Payment & Shipping Terms:

| Minimum Order Quantity: | Negotiable |

|---|---|

| Price: | Negotiable |

| Packaging Details: | 25kg barrel+ Pallet |

| Delivery Time: | Within 3-5 days after order confirmed |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 500mt per Year |

|

Detail Information |

|||

| Commodity: | Zirconium Silicate Beads | Product Name: | 65 Zirconia Beads |

|---|---|---|---|

| Usage: | Grinding Media | Main Chemical: | 65% ZrO2, 25-30% Al2O3 |

| Bulk Density: | ≥2.5 G/cm3 | True Gravity: | ≥4.0 G/cm3 |

| Vicker Hardness: | ≥700HV | Product Process: | Sintering |

| Highlight: | ceramic grinding media balls,zirconium silicate media |

||

Product Description

65 Zirconium Silicate Beads Zirconia Grinding Media 2.8-3.0 mm for Paint,Coating,Ink

1. Product Description of Zirconium Silicate Beads

Zirconium silicate beads contains 65% ZrO2,so it is also called as 65 zirconia beads. It plays an important

role in grinding application.

Compared with 95 Yttrium stabilized zirconium beads,65 zirconia beads has more competitive price/performance

ratio,which is suitable for grinding and dispersion of materials in low and medium viscosity.

2. Main Technical Data of 65 Zirconia Beads

| Commodity | Process | Chemical Index | Physical Index |

| 65 Zirconia Beads | Sintering | ZrO2 ≥ 65% | Bulk density:2.5g/cm3 |

| SiO2 25-30% | True Gravity ≥4.0 g/cm3 | ||

| Others ≤1.0% | Vicker Hardness≥700 HV | ||

| Particle Size(diameter) | 0.2-0.4mm 0.4-0.6mm 0.6-0.8mm,0.8-1.0mm, | ||

| 1.0-1.2mm,1.2-1.4mm,1.4-1.6mm,1.6-1.8mm,1.8-2.0mm | |||

| 2.0-2.2mm,2.0-2.5mm,2.5-3.0mm ,3.0-3.5mm | |||

| 4mm,5mm,6mm,7mm,8mm,10mm etc. | |||

| Remark: Special specification can be customized | |||

3. Main Aplications of Zirconium Silicate Beads

Grinding and dispersion for Calcium carbonate, kaolin, zircon sand, titanium dioxide, pigment, dye, ink,

paint,coating etc.

![]()

4. What is the difference between zirconium silicate beads and ceramic beads blasting media?

Firstly, different Production process: Zirconium silicate beads is made by sintering process,while ceramic

beads is made by melting process;

Secondly,ceramic beads blasting media contains 7-13% Al2O3,it is different from zirconium silicate beads

from the chemical composition.

Thirdly, zirconium silicate beads has higher bulk density and true gravity than the one of ceramic beads

blasting media.

Forthly, different particle size distribution: zirconium silicate beads has wide specifications from 0.2-10mm,

while ceramic beads has narrow particle size distribution from 0-0.850mm.

Fifth,different usage: zirconium silicate beads is used as grinding media,while ceramic beads is used as

blasting media.