700HV Hardness Ceramic Bead Blasting

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | B20, B30,B40, B60, B80,B100, B120, B170, B205, B400 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100KGS |

|---|---|

| Price: | Negotiation |

| Packaging Details: | 12.5kgs/barrel, 25kgs (2 barrels)/paper carton, or 25kgs barrels +pallet |

| Delivery Time: | 5-10 days |

| Supply Ability: | 1500mt per year |

|

Detail Information |

|||

| Commodity Name: | Ceramic Microbeads Blasting Media | Chemical Index: | ZrO2 60-68%, SiO2 25-30%, Al2O3 7-13% |

|---|---|---|---|

| Manufacturing Process: | Melting Method | Bulk Density: | 2.3g.cm3 |

| True Density: | 3.85g/cm3 | Hardness: | 700HV |

| Package: | 2*12.5kgs Barrels In Paper Cartons Or 25kgs Barrels +pallet | ||

| Highlight: | abrasive media blasting,ceramic cleaning media |

||

Product Description

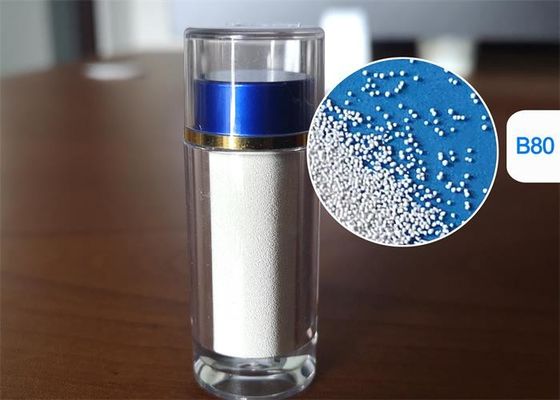

Golf club ball head surface finish Ceramic Bead Blasting media B80

DESCRIPTION OF CERAMIC MEDIA

The ceramic bead blasting also called bead blasting, ceramic blasting, ceramic blasting media, is a kind of Zirconia ceramic blasting media, with ZrO2 60-66%, size from B20 t0 B505, same as ZIRBLAST and MICROBLAST.

Blasting gives stainless steel a satin grey touch and other alloy to expose uniform metallic color, achieving smooth and non-reflective requirements on surface. This can be done with ceramic bead blasting.

Ceramic blasting beads mainly used for debluring and blast finishing in mobile phone middle frames and other 3C products, also in glass bottles molds cleaning, golf clubs surface finishing, painting surface pretreatment and shot peening in aerospace industry, automotive industry and medical instrument.

SPECIFICATION OF CERAMIC MEDIA

| Chemical Index | ZrO2 | SiO2 | Al2O3 |

| 60-65% | 25-30% | 7-13% | |

| Typical Value | 62.20% | 26.10% | 9.05% |

| Bulk Density | 2.3g/cm3 | ||

| Specific Density | 3.85g/cm3 | ||

| Vickers Hardness | 700HV | ||

| Grit size | B20 | B30 | B40 | B60 | B80 | B100 | B120 |

| Microns μm | 600-850 | 425-600 | 250-425 | 125-250 | 180-250 | 125-180 | 63-125 |

| Grit size | B125 | B170 | B205 | B400 | B505 |

Special sizes can be customized |

|

| Microns μm | 0-125 | 45-90 | 0-63 | 30-63 | 0-63 | ||

| Grit size | Z850 | Z600 | Z425 | Z300 | Z210 | Z150 | Z100 |

| Microns | 850-1180 | 600-850 | 425-600 | 300-425 | 210-300 | 150-210 | 100-150 |

FEATURES OF CERAMIC MEDIA

Surface finish consistency

01 Low breakdown

With features of less abrasive breakdown and almost no dust generation which in turn results in a cleaner working environment and better operator visibility

Comparing with glass beads, ceramic bears is of low breakdown rates up to 15:1 , thus enables it repeatable and consistent result to be achieved.

02 Narrow particle size distribution

The more centralized granularity can make the objects surface more uniform, and softer view in blasting process.

Contrast of Ceramic bead, glass beads and steel shot

| Parameter | Ceramic beads | Glass beads | Steel shot |

| Main ingredient | ZrO2+SiO2 | SiO2+NaO2 | C+Si+Mn+S+P |

| Vickers hardness | ≈700HV | ≈560HV | ≈700HV |

| Rockwell hardness | ≈60HRC | ≈46HRC | ≈60HRC |

| True density | 3.85g/cm3 | 2.6 g/cm3 | 7.8 g/cm3 |

| Particle size interval | 0.04-0.85mm | 0.045-0.85mm | 0.05-0.60mm |

| Particle shape | spherical | spherical | Fillet |

| Dust pollution | Very small | Big | small |

| Metal pollution | no | no | yes |

| Cycles | repeatedly 70-90 times |

Coking gas glass beads 1-2 times; Natural gas glass beads 3-4 times Under low pressure in blasting cabinet 9-12 times | repeatedly 80-100 times |

| Breakage rate under dry blasting |

1.20% | 10% | 1% |

| Service life | 8 times longther than glass beads under dry blasting; 25 times longer than glass beads under wet blasting | About ceramic sand 1/25 | high |

| power consumption | low | low | high |

| Equipment wear | low | low | high |

| Sandblasting effect | High finish and no discoloration of workpiece | High finish and white workpiece |

Low finish and blackened workpiece |

APPLICABLE EQUIPMENT

Suitable sand blasting machine:

Manual type series:

Manual closed type blasting machine, manual cart rotary blasting machine, double gun double station manual blasting machine, manual (automatic) roller dual-purpose blasting machine, manual closed pressure

Automatic series of sand blasting machine:

Automatic closed pressure blasting machine, automatic conveying type blasting machine, crawler type blasting machine, automatic turntable blasting machine, automatic turntable continuous pressure blasting machine, automatic conveying

Open type series of sand blasting machine:

Crankshaft inner wall automatic sand blasting machine

Blasting room series:

Pneumatic conveying type blasting room, mechanical conveying type blasting room, etc.

OUR SERVICE

Free Samples -1kgs

Different blasting workpieces, Different requirements for ceramic beads.

Our factory can provide consult solution, suggest the ceramic beads sizes according to the workpiece you handle and provide 1kgs ceramic beads samples for free.

OEM customize same ceramic beads with your samples or requirements.

Our factory has our own test lab., with high precision chemical and particle size detection instruments. You can send ceramic beads samples, then we will test and analysis it and customize same ceramic beads with your samples or according to your customer requirements.

Quality Guarantee

Guarantee our ceramic beads has no quality problems, and in case any problems are found,

We accept return and/or exchange.

APPLICATION OF CERAMIC MEDIA

l In Sandblasting

1) 3C products - Sandblasting Finishing

2) Kitchen Industry-Sandblasting finishing

3) Golf club - Sandblasting finishing

4) Casting and forging parts, welded parts, heat-treated parts - Sandblast Cleaning

5) Pipeline - Sandblast Cleaning

6) Molds - Sandblast cleaning

7) Electroplating, painting, anode-Surface Pretreatment

8) Hardware parts - Sandblasting to improve lubrication conditions

l In shot peening

1) Aerospace industry-Shot Peening

2) Automotive industry-Sandblasting reinforcement/ Shot Peening

3) Machinery, Medical Instrument - Sandblast finishing/shot peening

![]()