B20 Ceramic Beads Media Zirconium Silicate For Surface Finishing Of Glass Beads

Product Details:

| Place of Origin: | Shanxi,China |

| Brand Name: | Zhengtong |

| Certification: | ISO9001,ISO14001 |

| Model Number: | B20,B30,B40,B60,B80,B100,B120,B150,B170,B205,B400 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100KGS |

|---|---|

| Price: | Negotiation |

| Packaging Details: | 2*12.5kg drum+Carton Box+pallet,25kg drum+pallet |

| Delivery Time: | 3-10 days depending on the order quantity |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 200mt per month |

|

Detail Information |

|||

| Product Name: | Zirconium Silicate Blasting Beads | Usage: | Moulds Surface Cleaning |

|---|---|---|---|

| Specification: | B20-B505 | Process: | Melting |

| Bulk Density: | 2.3g/cm3 | Vicker Hardness: | 700HV |

| High Light: | Zirconium Silicate Blasting Beads Media,B20 Ceramic Beads Media Of Glass Beads,Ceramic Beads Media For Surface Finishing |

||

Product Description

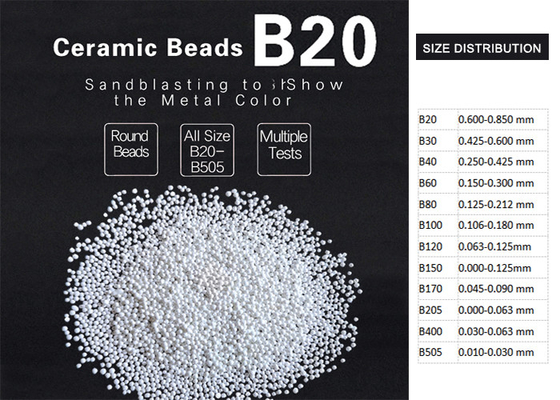

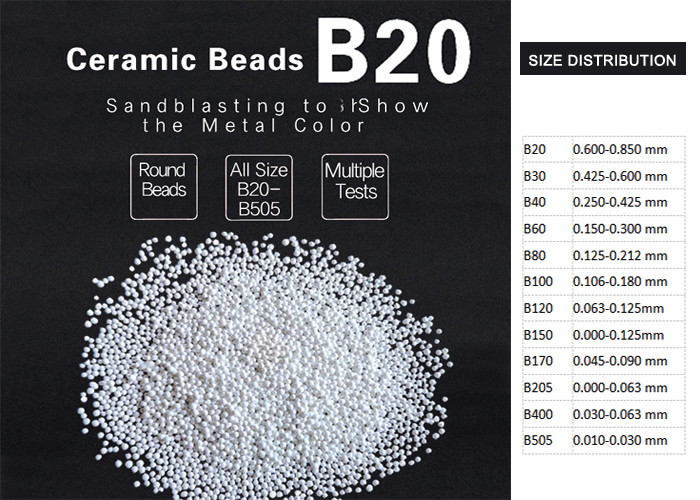

Ceramic Beads B20 size 0.600-0.850mm 20 times longer service life than glass beads

1. Description of Ceramic Beads B20

Ceramic Beads is a kind of more environmentally friendly, dust-free, clean blasting abrasive media, it's an ideal alternative of glass beads

It has high hardness, long blasting service life and good elasticity, especially suitable for aluminum alloy workpieces.

Ceramic beads sandblasting can create varying degrees of roughness on metal surfaces, as well as remove shine to create a smooth, fine-grained matte finish.

Widely used for blasting surface finish, blasting cleaning and blast pretreatment before coatings.

Usually for metal parts of alu, alu alloy, steel, stainless steel copper and other alloys.

2. Main Technical Index of Ceramic Beads B20

| Commodity | Main Chemical Index | Main Physical Index |

|

Blasting Ceramic Beads

(Melting Method) |

ZrO2 60-66% | Bulk Density: 2.3g/cm3 |

| SiO2 25-30% | True Specific Gravity: 3.85 g/cm3 | |

| Al2O3 7-13% |

Vickers Hardness: 700 kg /mm2 |

| Particle Size | |

| B20: 0.600-0.850mm | B100: 0.125-0.180mm |

| B30: 0.425-0.600mm | B120: 0.063-0.125mm |

| B40: 0.250-0.425mm | B170: 0.045-0.090mm |

| B60: 0.125-0.250mm | B205: 0.000-0.063mm |

| B80: 0.180-0.250mm | B400: 0.030-0.063mm |

| Remark: Special specification can be customized | |

3. Main Application of Ceramic Beads B20

Ceramic beads sandblasting media can clean the surface contamination of different metal materials, including

- Alu&Alu alloy

- Steel &stainless steel

- Copper

- Aluminum-magnesium alloy

![]()

Ceramic beads sandblasting can also make the metal surface reveal a uniform and consistent metal color, visual appearance more beautiful.

Compared with glass beads, the ceramic beads quality is higher, service life is increased by 20 times, the number of material changes is reduced, and the work efficiency is improved.

Ceramic beads is not easy to break, no dust, clean and environmentally friendly, no hidden danger of silicosis, and harmless to the human body.

5. Applicable Equipment of Ceramic Beads B20

Manual Sandblasting machine;

Automatic Blasting Machine;

Open Blasting Machine;

Sandblasting Room

6. Package of Ceramic Beads B20

25kg drum+pallet

Special packages can be customized.