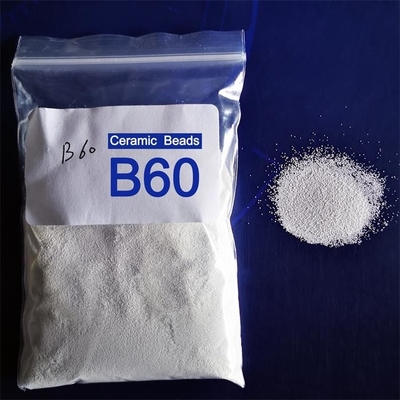

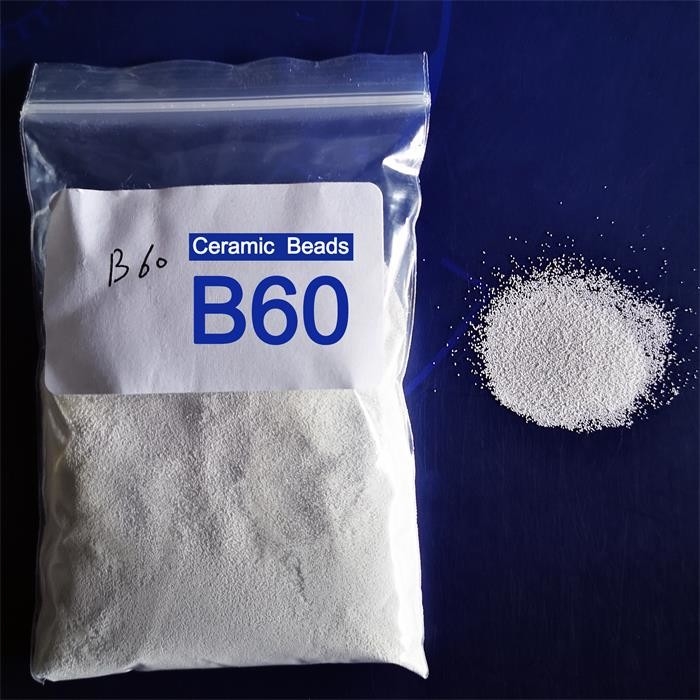

B60 Ceramic Bead Blasting Abrasive 0.150-0.300 For Alu Alloy Parts Sandblasting Finish

Product Details:

| Place of Origin: | China |

| Brand Name: | ZIRNANO |

| Certification: | ISO9001,ISO14001 |

| Model Number: | B60:0.150-0.300MM |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100KGS |

|---|---|

| Price: | Negotiable |

| Packaging Details: | 25kg barrel+pallet or 2*12.5kg barrel+ paper carton box + pallet |

| Delivery Time: | 3-5 days after order confirmed |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 200mts per month |

|

Detail Information |

|||

| Main Material: | 60-66% ZrO2 | Usage: | Sandblasting Media For Metal Surface Treatment |

|---|---|---|---|

| Commodity: | Ceramic Beads | Product Name: | Ceramic Blasting Media |

| Bulk Density: | 2.3 G/cm3 | True Gravity: | 3.85 G/cm3 |

| Vicker Hardness: | 700 HV | Shape: | Solid Round Ball |

| High Light: | Ceramic Bead Blasting Abrasive,B60 Ceramic Bead Blasting,0.300 Ceramic Bead Blasting |

||

Product Description

Ceramic Bead Blasting abrasive B60: 0.150-0.300 for alu alloy parts sandblasting finish

- Description

Ceramic Beads blasting abrasive is a no dust and no iron pollution ceramic media for metal surface sandblasting treatment, it is zirconia based abrasive, produced in ore furnace by smelting zirconia sand and little aluminium oxide, and then blowed into micro beads, sizes from B20-B505. It is with very fine microstructure featured strong mechanical resistance and high toughness, low-dust emission,especially suitable for metal surface sandblasting treatment.

Widly used for alu alloy parts sandblasting surface finish.

- Chemical Index:

ZrO2 60-66%

SiO2 25-30%

Al2O3 7-13%

- Physical Index

Processing: Melting

Bulk Density: 2.3g/cm3

True Specific Gravity: 3.97 g/cm3

Vickers Hardness: 700 kg /mm2

- Sizes

| B20 | 0.600-0.850 mm |

| B30 | 0.425-0.600 mm |

| B40 | 0.250-0.425 mm |

| B60 | 0.150-0.300 mm |

| B80 | 0.125-0.212 mm |

| B100 | 0.106-0.180 mm |

| B120 | 0.063-0.125mm |

| B150 | 0.000-0.125mm |

| B170 | 0.045-0.090 mm |

| B205 | 0.000-0.063 mm |

| B400 | 0.030-0.063 mm |

| B505 | 0.010-0.030 mm |

- Application

Widly used for sandblasting surface matte finish for alu alloy parts.

For example, computer base, the TV baseand mobile phone shells, the cabinet handle and the desk partitions are all aluminum alloy.

And these aluminum alloy products have one thing in common, that is, the surface looks very smooth, but not too bright, with a low-key matte effect. That's because the aluminum alloy material is passed through the sandblasting machine and get matte finish.

In the sandblasting process, the fine and dense ceramic beads makes even small pits on the surface of the aluminum profile, which are almost invisible to the naked eye and present in front of us. The aluminum profile is still smooth, but the visual effect has changed from bright to matte. The particle size of ceramic beads is different, and the effect of spraying on the profile is also divided into thickness. After sandblasting, the aluminum profile is subjected to anodizing treatment to form a dense transparent oxide film on the surface to increase corrosion resistance.

![]()

- Applicable Equipment:

Ceramic beads can be used in below sandblasting machine:

1. Manual sandblasting machine

2. Automatic sandblasting machine

3. Open sandblasting machine

4. Sandblasting room