Zero Ferrous Contamination Ceramic Bead Blasting Media For Metal Surface Finish

Product Details:

| Place of Origin: | China |

| Brand Name: | Zirnano |

| Certification: | ISO9001,ISO14001,ROHS,SGS |

| Model Number: | B20-B505 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100KGS |

|---|---|

| Price: | Negotiable |

| Packaging Details: | 25 KG (12L)Barrel + Pallet; 2*12.5 KG Barrel+ Carton Box+ Pallet |

| Delivery Time: | Within 3-5 days after order confirmed |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 3000 MTS Per Year |

|

Detail Information |

|||

| Commodity: | Ceramic Beads | Product Name: | Ceramic Blasting Media |

|---|---|---|---|

| Application: | Sandblasting | Mohs Hardness: | 8 |

| Bulk Density: | 2.3 G/cm3 | True Gravity: | 3.85g/cm3 |

| Specification: | B20 850-600μm | Vicker Hardness: | 700 HV |

| High Light: | abrasive blasting media,ceramic bead blasting media |

||

Product Description

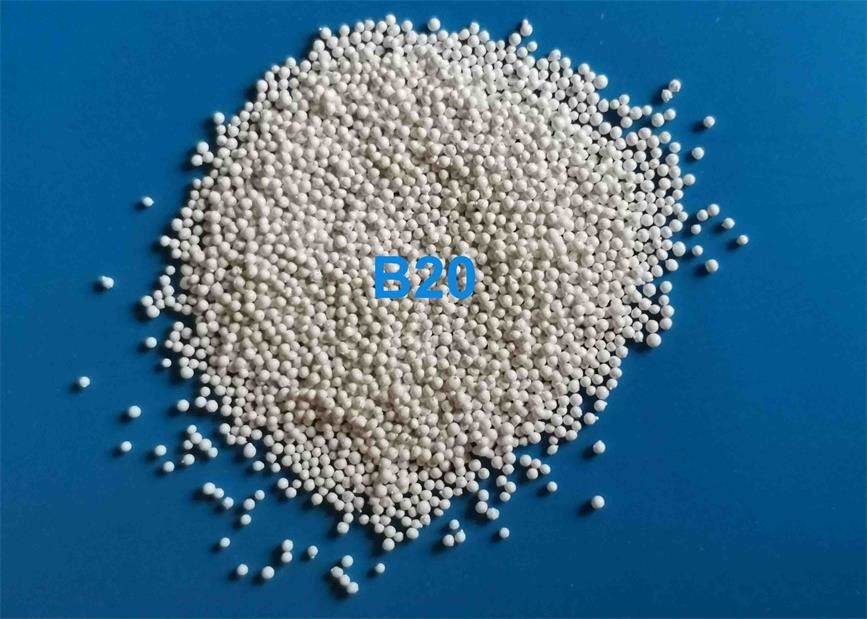

Zero Ferrous Contamination Ceramic Beads Blasting Media B20-B505 for Metal Surface Finish

1. Product Description of Ceramic Bead Blasting Media

Ceramic Beads has round solid shape,smooth surface,good elasticity,it can be rebounded in multi-angle

in blasting process,which is especially suitable for metal surface finish. There is little dust generated in

the whole blasting process,so it is also one clean blasting media compared with the one of glass beads.

2. The comparation between Ceramic Beads and Glass Beads

| Item | Ceramic Blasting Beads | Glass Beads |

| Chemical Index | ZrO2 60-66% SiO2 25-30% Al2O3 7-13% |

Si02:>65%,Na2O<14.0% Ca0>8.0%,Mg0>2.5% Ai203 0.5-2.0% Fe203:0.15 |

| Particle Size | B20: 0.600-0.850mm | 30#:0.425-0.850mm |

| B30:0.425-0.600mm | 40#: 0.425-0.600mm | |

| B40:0.250-0.425mm | 60#:0.300-0.425mm | |

| B60:0.150-0.300mm | 80#:0.150-0.300mm | |

| B80:0.125-0.212mm | 100#:0.106-0.212mm | |

| B100:0.106-0.180mm | 120#:0.106-0.150mm | |

| B120:0.063-0.125mm | 150#:0.075-0.150mm | |

| B150:0.000-0.125mm | 180#:0.075-0.106mm | |

| B170:0.045-0.090mm | 220#:0.053-0.106mm | |

| B205: 0.000-0.063mm | 280#:0.045-0.075mm | |

| B400: 0.030-0.063mm | 320#:0.001-0.050mm | |

| B505: 0.010-0.030mm | / | |

| Vickers Hardness | ≥700 HV | ≥560HV |

| True Specific Gravity | ≥3.85 g/cm3 | ≥2.5g/cm3 |

| Bulk Density | ≥2.3g/cm3 | ≥1.5g/cm3 |

| Particle Size | 0.010-0.85mm | 0.001-0.850mm |

| Usage | Blasting Media | Blasting Media |

| Ferrous Contamination | No Ferrous | No Ferrous |

| Dust Pollution | Little | Large |

| Recyclable Times | Multiple | One time or twice |

| Power consumption | Low | Low |

| Equipment Wear Rate | Low | Low |

| Blasting Effect | High finish No discoloration |

High finish White discoloration |

Seen from the above chart, it is easy to see that ceramic bead has the advantages of higher hardness,

low dust generation,longer service life,better blasting effect in visual sight compared with the one of glass

beads,so ceramic beads can replace galss beads where requires a clean and better blasting effect.

3. The consumption contrast between Ceramic Beads & Glass Beads

| For the same Treated Parts | Blasting Media | Month Consumption | Solid Waste Q'ty |

Total cost |

| Die-cast aluminum parts | Glass Beads 60# | 7.0mts | large quantity | High |

| Ceramic Beads B60 | 0.1mt | Small quantity | Low |

The above is one true testing result from our client,obviously ceramic beads has lower bead consumption,

it not only reduces the blasting cost and disposal cost of solid waste greatly,but also provides one clean

working condition for the operators.

4. Why Ceramic Beads is one Popular Blasting Media?

Ceramic beads has extremely fine microstructure, which provides good impact strength and toughness,

so it is suitable for sandblastig for metal parts and light alloy parts such as alluminum & alluminum alloy

parts,titanium alloy,magnesium alloy as well as stainless steel parts and copper parts.

![]()

5. Precautions When Using Ceramic Beads for the first time

Please kindly open 1/3 to 1/2 vest of dust collector when using ceramic bead for the first time,because

ceramic beads need the wind to be recycled. This is different from glass beads, when using galss beads,the

vest of dust collector is sealed completely.

6. Why Choose Us?

Professional Manufacturer of ceramic beads,annual output over 3000mts

Equipped the most advanced production line,testing equipment, as well as professional technical staffs and

7*24h technical support;

Strict quality control and quality assurance, products will be inspected by each

Shipment,even for the free sample in small quantity;

Multiple Authentication,Certificated by ISO9001 ISO14001,SGS,ROHS;

Stable supplier of Foxconn,Ujiden,Samsung Electronics,Tongda Group etc

Products in good quality & stable performance,competitive price,flexible payment terms,prompt delivery etc.