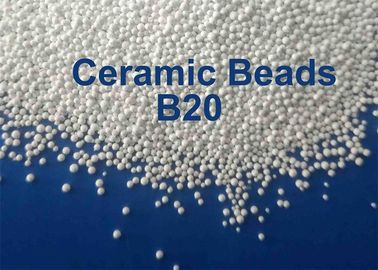

High Hardness Zirconia Ceramic Blasting Media ZrO2 60 - 66% B20,B60,B120,B205 Surface Pretreatment Material

Product Details:

| Place of Origin: | Shanxi,China |

| Brand Name: | FUDA |

| Certification: | ISO9001,ISO14001 |

| Model Number: | B20,B30,B40,B60,B80,B100,B120,B150,B170,B205,B400 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100KGS |

|---|---|

| Price: | Negotiation |

| Packaging Details: | 2*12.5kg drum+Carton Box+pallet,25kg drum+pallet |

| Delivery Time: | 3-10 days depending on the order quantity |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 200mt per month |

|

Detail Information |

|||

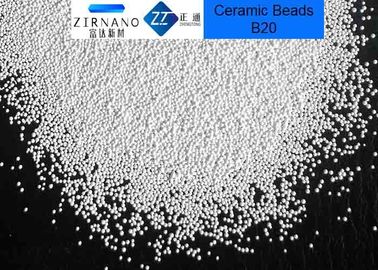

| Product Name: | Ceramic Beads | Color: | White |

|---|---|---|---|

| Bulk Density: | 2.3 G/cm3 | Vicker Hardness: | 700 HV |

| Usage: | Surface Pretreatment,Sandblasting,Deburring,Mold Cleaning | Specification: | B20:0.600-0.850mm |

| High Light: | bead blasting material,ceramic bead blasting media |

||

Product Description

High Hardness Zirconia Ceramic Blasting Media ZrO2 60 - 66% B20,B60,B120,B205 for Surface Pretreatment

1. Description of Zirconia Ceramic Blasting Media ZrO2 60 - 66% B20,B60,B120,B205 for Surface Pretreatment

Ceramic Blasting Media is one kind of zirconia beads,it contains 60-66% ZrO2,which selects the zirconium

sand as main materials,then fused under high temperature.

It is widely used as one blasting media and are able to replace the steel beads where ferrous contamination

is not allowed.

2. Main Technical Data of Zirconia Ceramic Blasting Media

| Description | Main Chemical Index | Main Physical Index |

| Ceramic Beads | ZrO2 60-66% | Processing method: Melting |

| SiO2 25-30% | Bulk Density: 2.3g/cm3 | |

| Al2O3 7-13% | True Specific Gravity: 3.85 g/cm3 | |

| / | Vickers Hardness: 700 kg /mm2 |

| Particle Size | |

| B20: 0.600-0.850mm | B100: 0.125-0.180mm |

| B30: 0.425-0.600mm | B120: 0.063-0.125mm |

| B40: 0.250-0.425mm | B170: 0.045-0.090mm |

| B60: 0.125-0.250mm | B205: 0.000-0.063mm |

| B80: 0.180-0.250mm | B400: 0.030-0.063mm |

| Remark: Special specification can be customized | |

3. Main Product Features of Zirconia Ceramic Blasting Media

No contamination and damage to the workpieces

Ceramic beads is white color, so no surface contamination to the workpieces ; the round shape and smooth

surface, which also ensure it no damage to the workpieces;

High hardness, good elasticity

Round ceramic beads could be rebounded in multi angles when sandblasting the workpieces ,especially

suitable for the metal products and achieve good gloss in the surface;

Long service life and good sandblasting effect

Compared to glass beads, the service life could be prolonged at least 20- 30 times and also could

achieve better visual effect and texture as well as lower toughness.

Superior smoothness and No ferrous pollution to the work-pieces

Compared to steel beads, it has superior smoothness,it can be used in peening applications in the

place of steel shots where ferrous contamination is not acceptable.

High efficiency and Low energy consumption

Not easy to breakdown during blasting process,only few ceramic beads will be broken in the process

of usage,the non-broken ones will maintain the original features inshape,particle size,hardness as

well as smoothness,then it is recyclable,and can reduce the refueling times, improve working efficiency,

then finally save the production cost.

The low energy consumption will offers a certain thickness surface strengthening layer ,then effectively

improve the fatigue life of the metal surface and eliminate the stress.

Environmental protection

No dust, clean, and no hidden danger of silicosis, it is harmless to the human body.

4. Main Application of Zirconia Ceramic Blasting Media

Widely used in 3C products’ surface finishing treatment such as the metal or plastic surface or its built-in

parts of computer,mobile phone,camera etc.;

![]()

Used for blasting and finishing media for various mechanical products to strengthen the original metal color

and enhance the visual effect and texture; especially suitable for the treatment of light metal such as

aluminium alloy,titanium alloy,stainless steel etc.

![]()

Sand blasting for hardware parts to deburr, clean and descale complex shapes of all sizes and materials;

![]()

Clean the inner or outer walls of various metal pipes such as cooper pipes and steel pipes etc.;

![]()

Surface cleaning to remove the rust,oil stain and impurities of various molds such as glass bottles,tires

and dies etc.;

![]()

Shot peening for aviation& aerospace and shipbuilding industry such as springs,gears and other

components;Anti-fatigue and strengthening treatment in automotive industry such as gearbox gears,

automotive aluminum hubs etc.;

![]()

Comparation effect before and after ceramic bead blasting

![]()

5. Product Package of Zirconia Ceramic Blasting Media:

2*12.5kg drum+carton box+ pallet

25kg drum+pallet

Special packages can be customized.

![]()

6. FAQ

Are you direct Manufacturer of Zirconia Ceramic Beads ?

Yes,we are professional manufacturer,equipped with the most advanced production line and testing

equipment;

Are you able to provide free samples?

Yes, few quantity free sample is avialable.

Could you please name your some clients?

Yes, our clients includes Foxconn, Samsung Electronics etc.

If you have any other questions,please contact me freely.