White Sinterred Zirconium 4 , 1.8 - 2.0mm 1.1 KN Zirconium Silicate Media

Product Details:

| Place of Origin: | Shanxi,China |

| Brand Name: | FUDA |

| Certification: | ISO9001,ISO14001 |

| Model Number: | 0.6-10mm |

Payment & Shipping Terms:

| Minimum Order Quantity: | 25kg |

|---|---|

| Price: | Negotiation |

| Packaging Details: | 25kg drum+Pallet, 25kg Bag+Pallet,Ton Bag |

| Delivery Time: | 3-14days depending on the order quantity |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 3000MT per Year |

|

Detail Information |

|||

| Product Name: | Zirconia Grinding Media | Usage: | Grinding Media For Pigment , Coating |

|---|---|---|---|

| Compressive Strength: | ≥1.1 KN (Φ2mm) | Bulk Density: | ≥2.5 G/cm3 |

| Mohs Hardness: | >8 Mohs | True Gravity: | ≥ 4.0g/cm3 |

| High Light: | zirconia sintering beads,ceramic grinding media balls |

||

Product Description

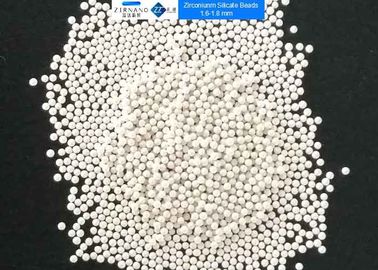

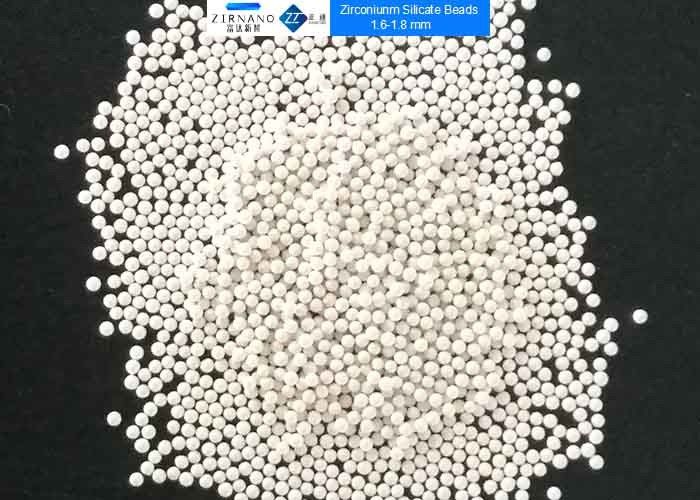

Competitive Price Sinterred Zirconium Silicate Beads Zirconia Grinding Media 1.8-2.0mm

1. Description of Sinterred Zirconium Silicate Beads Zirconia Grinding Media

The Zirconium silicate beads are made by zircon sand,rolled into embryos after fine grinding,then

finally formed in a sintered phasing process.Its medium density and hardness are suitable for the

dispersion and grinding of medium and low viscosity slurries. It also has the characteristics of high

compressive strength and low abrasion loss. It is an economic grinding media compared with other

zirconia beads.

![]()

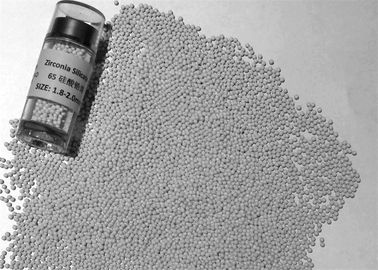

2. Main technical index of Zirconium Silicate Beads

| Commodity | Typical Chemical Index | Main Physical Index |

|

Zirconium Silicate Beads (Sinterred Process) |

ZrO2 ≥65% | True Gravity ≥4.0g/cm3 |

| SiO2 25-30% | Bulk Density ≥2.5g/cm3 | |

| Others ≤1.0% | Vicker Hardness ≥900 HV | |

| Sintering process | compressive strength ≥1.1KN (Φ2mm) |

| Particle Size | ||||||

| Φ0.6-0.8mm,Φ0.8-1.0mm,Φ1.0-1.2mm,Φ1.2-1.4mm,Φ1.4-1.6mm | ||||||

| Φ1.6-1.8mm,Φ1.8-2.0mm,Φ2.5-3.0mm ,Φ3.0-3.5mm | ||||||

| Φ4mm,Φ5mm,Φ6mm,Φ7mm,Φ8mm,Φ10mm etc. | ||||||

| Special products can be customized |

3. Prouction Process of Zirconium Silicate Beads

![]()

4. Main Features of Zirconium Silicate Beads

Dense particles,high gravity and hardness,better grinding efficiency;

Good sphericity,smooth surface,low abrasion loss,little damage to the equipment and

no pollution in the grinding process,then make sure the purity and quality of treated

materials;

High cost -effective,long time life;

Good stability,Anti-Acid & alkali corrosion.

5. Main Application of Zirconium Silicate Beads

Grinding media for Pigment,coating etc.

![]()

Grinding meida for ink,paint etc.

![]()

Grinding media for Pesticides,Titanium Dioxide etc

![]()

Grinding media for Calcium Carbonate and Kaolin etc.

![]()

6. Products Package

25kg drum+pallet, 25kg bag +pallet, ton bag,special packages can be customized.

![]()

7. Why Choose Us?

Professional manufacturer,Providing good products with stable quality & favorable price;

Equipped with the most advanced production line and testing equipments,certificatd by

ISO9001&14001;

Products has been exported to USA,South Korea,Vietnam,Japan etc.